Aluminum circle

Haomei Aluminum is both a aluminum circle/disc manufacturer and supplier with 18 years experience.

we use the finest raw material to improve the product quality, guaranteeing the quality of our aluminum Circle lives to national standards. haomei aluminum can manufacture aluminum Circle with many tempers, such as O,H12,H14 etc, and it can be cut to size at customers’ need.

Haomei aluminum Circle Features

- Wide range of selection on aluminum circles' size including customized shape and size.

- Excellent Surface Quality for lighting reflectors.

- Excellent deep drawing and spinning quality.

- We provide heavy guage circles with thicknesses up to 6mm thick which is ideal for cookware.

- Anodizing Quality and Deep Drawing Quality which is suitable for cookware as well.

- RoHS and REACH compliance.

- Well-Protected Packing

We would like to highlight our aluminum circle,aluminum strip,aluminum sheet,aluminum plate,aluminum ROPP cap materials, aluminum hot rolled plate and aluminum tread plate with good quality and competitive price.

aluminum circle Range

Alloy |

Temper |

Specification |

|

Thickness(mm) |

Diameter(mm) |

||

1050,1060

1070,1100,3003 |

O,H12,H14 |

0.40—6.0 |

20--1200 |

Product Properties

TEMPER |

THICKNESS(mm) |

TENSILE STRENGTH |

ELONGATION% |

Standard |

||||||||||||||||

HO |

0.36-6 |

60-100 |

≥ 20 |

GB/T91-2002

|

||||||||||||||||

H12 |

0.5-6 |

70-120 |

≥ 4 |

|||||||||||||||||

H14 |

0.5-6 |

85-120 |

≥ 2 |

|||||||||||||||||

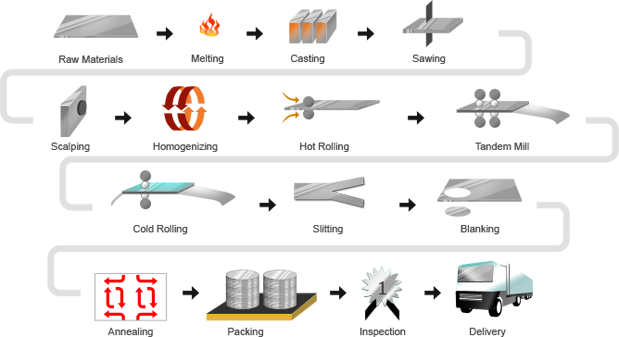

Product Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Chemical Properties(WT.%)

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ca |

V |

Ti |

Other |

Min.A1 |

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.5 |

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.6 |

1070 |

0.25 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

- |

0.04 |

- |

0.05 |

0.03 |

0.03 |

99.7 |

1100 |

0.95 |

0.05-0.2 |

0.05 |

- |

- |

- |

0.1 |

- |

- |

- |

0.05 |

99 |

|

3003 |

0.6 |

0.7 |

0.05-0.2 |

1.0-1.5 |

- |

- |

- |

0.1 |

- |

- |

- |

0.15 |

96.95-96.75 |

Diameter List

≧20 |

≧140 |

≧170 |

≧200 |

≧250 |

≧300 |

≧400 |

≧500 |

≧600 |

≧700 |

≧800 |

20 |

140 |

170 |

200 |

250 |

300 |

400 |

500 |

600 |

700 |

800 |

25 |

141 |

172 |

203 |

252 |

305 |

405 |

505 |

610 |

705 |

810 |

93 |

142 |

173 |

205 |

254 |

310 |

410 |

510 |

615 |

710 |

838 |

100 |

143 |

175 |

210 |

255 |

312 |

420 |

515 |

619 |

720 |

890 |

105 |

144 |

176 |

211 |

258 |

315 |

425 |

520 |

630 |

730 |

902 |

109 |

145 |

177 |

212 |

260 |

320 |

430 |

525 |

635 |

740 |

945 |

110 |

147 |

178 |

215 |

267 |

325 |

435 |

530 |

645 |

760 |

960 |

112 |

149 |

180 |

216 |

268 |

330 |

440 |

540 |

650 |

770 |

1000 |

115 |

150 |

181 |

217 |

270 |

335 |

445 |

545 |

655 |

780 |

1150 |

118 |

153 |

182 |

218 |

272 |

340 |

450 |

550 |

665 |

1200 |

|

120 |

154 |

183 |

220 |

274 |

345 |

455 |

560 |

670 |

||

121 |

155 |

184 |

221 |

275 |

350 |

460 |

565 |

680 |

||

122 |

157 |

185 |

222 |

277 |

355 |

465 |

570 |

690 |

||

123 |

158 |

188 |

225 |

278 |

360 |

470 |

575 |

|||

124 |

160 |

190 |

226 |

280 |

364 |

475 |

580 |

|||

127 |

161 |

192 |

230 |

282 |

368 |

480 |

585 |

|||

128 |

162 |

193 |

233 |

285 |

370 |

485 |

||||

129 |

163 |

195 |

235 |

290 |

375 |

490 |

||||

130 |

164 |

198 |

237 |

292 |

380 |

495 |

||||

132 |

165 |

238 |

293 |

385 |

||||||

133 |

166 |

240 |

295 |

390 |

||||||

134 |

167 |

242 |

395 |

|||||||

135 |

168 |

245 |

||||||||

136 |

169 |

249 |

||||||||

137 |

||||||||||

138 |

||||||||||

139 |

* Please enquire if you are interested in products outside the above ranges

Diameter Tolerances

|

Blanked and Sheared Circle Products |

|||

| Thickness(mm) | Diameter Range (D)(mm) | |||

| D <= 455 | 455 < D <=1000 | 1000 < D <=1200 | ||

| .4 - 6.0 | +/-.079 | +/-.099 | +/-.015 | |

|

||||