For more aluminium circle technical documents, Download free in PDF form !!

Quality policy

The quality policy of Haomei is to establish, implement, and maintain an effective assurance system based on ISO 9001 with the full participation of all employees in the process of continuous quality improvement and quality assurance practices resulting in total customer satisfaction. By encouraging open communication, we are dedicated to achieve true and sincere partnership with both internal and external customers resulting in total customer satisfaction.

The purpose of our quality system is to continuously improve the quality of our products, our services, and productivity in order to achieve internal and external customer satisfaction.

Product Range

Alloy |

Temper |

Specification |

|

Thickness(mm) |

Diameter(mm) |

||

1050,1060 1070,1100,3003 |

O,H12,H14 |

0.40—6.0 |

20--1200 |

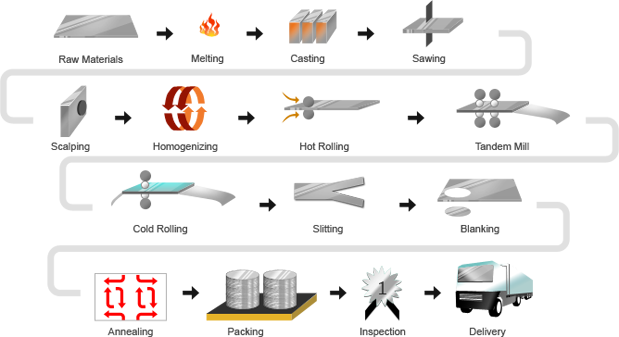

Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Chemical Properties

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ca |

V |

Ti |

Other |

Min.A1 |

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.5 |

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.6 |

1070 |

0.25 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

- |

0.04 |

- |

0.05 |

0.03 |

0.03 |

99.7 |

1100 |

0.95 |

0.05-0.2 |

0.05 |

- |

- |

- |

0.1 |

- |

- |

- |

0.05 |

99 |

|

3003 |

0.6 |

0.7 |

0.05-0.2 |

1.0-1.5 |

- |

- |

- |

0.1 |

- |

- |

- |

0.15 |

96.95-96.75 |

Charateristics and Applications

Section |

Alloy |

Characteristics |

Application |

1000 series |

AA1050 |

Excellent in forming, welding and corrosion resistance though lacking the strength |

Kitchen Appliances, Reflector Panel, Traffic sign, Decorative Products, Conductive Material, Construction Material, Electrical Appliances, etc |

AA1060 |

|||

AA1070 |

|||

AA1100 |

|||

AA1200 |

|||

3000 series |

AA3003 |

Have slightly higher strength than AA1100 and excellen t in forming, welding and corrosion resistance |

Kitchen Utensils, Interior & Exeterior Materials for Construuction, etc |

Diameter List

≧20 |

≧140 |

≧170 |

≧200 |

≧250 |

≧300 |

≧400 |

≧500 |

≧600 |

≧700 |

≧800 |

20 |

140 |

170 |

200 |

250 |

300 |

400 |

500 |

600 |

700 |

800 |

25 |

141 |

172 |

203 |

252 |

305 |

405 |

505 |

610 |

705 |

810 |

93 |

142 |

173 |

205 |

254 |

310 |

410 |

510 |

615 |

710 |

838 |

100 |

143 |

175 |

210 |

255 |

312 |

420 |

515 |

619 |

720 |

890 |

105 |

144 |

176 |

211 |

258 |

315 |

425 |

520 |

630 |

730 |

902 |

109 |

145 |

177 |

212 |

260 |

320 |

430 |

525 |

635 |

740 |

945 |

110 |

147 |

178 |

215 |

267 |

325 |

435 |

530 |

645 |

760 |

960 |

112 |

149 |

180 |

216 |

268 |

330 |

440 |

540 |

650 |

770 |

1000 |

115 |

150 |

181 |

217 |

270 |

335 |

445 |

545 |

655 |

780 |

1150 |

118 |

153 |

182 |

218 |

272 |

340 |

450 |

550 |

665 |

1200 |

|

120 |

154 |

183 |

220 |

274 |

345 |

455 |

560 |

670 |

||

121 |

155 |

184 |

221 |

275 |

350 |

460 |

565 |

680 |

||

122 |

157 |

185 |

222 |

277 |

355 |

465 |

570 |

690 |

||

123 |

158 |

188 |

225 |

278 |

360 |

470 |

575 |

|||

124 |

160 |

190 |

226 |

280 |

364 |

475 |

580 |

|||

127 |

161 |

192 |

230 |

282 |

368 |

480 |

585 |

|||

128 |

162 |

193 |

233 |

285 |

370 |

485 |

||||

129 |

163 |

195 |

235 |

290 |

375 |

490 |

||||

130 |

164 |

198 |

237 |

292 |

380 |

495 |

||||

132 |

165 |

238 |

293 |

385 |

||||||

133 |

166 |

240 |

295 |

390 |

||||||

134 |

167 |

242 |

395 |

|||||||

135 |

168 |

245 |

||||||||

136 |

169 |

249 |

||||||||

137 |

||||||||||

138 |

||||||||||

139 |

* Please enquire if you are interested in products outside the above ranges

Diameter Tolerances

|

Blanked and Sheared Circle Products |

|||

| Thickness(mm) | Diameter Range (D)(mm) | |||

| D <= 457 | 457 < D <=1000 | 1000 < D <=1220 | ||

| .31 - 6.35 | +/-.079 | +/-.099 | +/-.015 | |

|

||||